- 您现在的位置:买卖IC网 > Sheet目录479 > MMFT5P03HDT1 (ON Semiconductor)MOSFET P-CH 30V 3.7A SOT223

�� �

�

MMFT5P03HD�

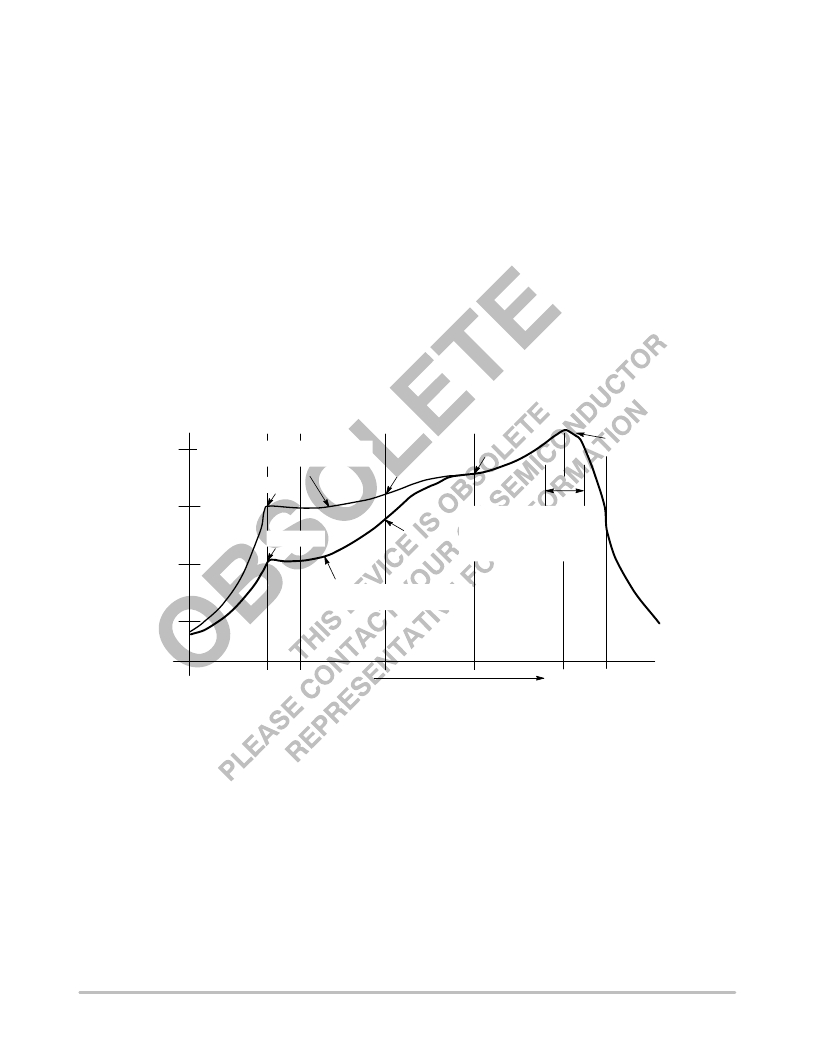

�TYPICAL� SOLDER� HEATING� PROFILE�

�For� any� given� circuit� board,� there� will� be� a� group� of�

�control� settings� that� will� give� the� desired� heat� pattern.� The�

�operator� must� set� temperatures� for� several� heating� zones�

�and� a� figure� for� belt� speed.� Taken� together,� these� control�

�settings� make� up� a� heating� “profile”� for� that� particular�

�circuit� board.� On� machines� controlled� by� a� computer,� the�

�computer� remembers� these� profiles� from� one� operating�

�session� to� the� next.� Figure� 16� shows� a� typical� heating�

�profile� for� use� when� soldering� a� surface� mount� device� to� a�

�printed� circuit� board.� This� profile� will� vary� among�

�soldering� systems,� but� it� is� a� good� starting� point.� Factors�

�that� can� affect� the� profile� include� the� type� of� soldering�

�system� in� use,� density� and� types� of� components� on� the�

�board,� type� of� solder� used,� and� the� type� of� board� or�

�substrate� material� being� used.� This� profile� shows�

�temperature� versus� time.� The� line� on� the� graph� shows� the�

�actual� temperature� that� might� be� experienced� on� the� surface�

�of� a� test� board� at� or� near� a� central� solder� joint.� The� two�

�profiles� are� based� on� a� high� density� and� a� low� density�

�board.� The� Vitronics� SMD310� convection/infrared� reflow�

�soldering� system� was� used� to� generate� this� profile.� The� type�

�of� solder� used� was� 62/36/2� Tin� Lead� Silver� with� a� melting�

�point� between� 177� ?� 189� °� C.� When� this� type� of� furnace� is�

�used� for� solder� reflow� work,� the� circuit� boards� and� solder�

�joints� tend� to� heat� first.� The� components� on� the� board� are�

�then� heated� by� conduction.� The� circuit� board,� because� it� has�

�a� large� surface� area,� absorbs� the� thermal� energy� more�

�efficiently,� then� distributes� this� energy� to� the� components.�

�Because� of� this� effect,� the� main� body� of� a� component� may�

�be� up� to� 30� degrees� cooler� than� the� adjacent� solder� joints.�

�STEP� 1�

�PREHEAT�

�STEP� 2�

�VENT�

�STEP� 3�

�HEATING�

�STEP� 4�

�HEATING�

�STEP� 5�

�HEATING�

�STEP� 6�

�VENT�

�STEP� 7�

�COOLING�

�ZONE� 1�

�“SOAK”� ZONES� 2� &� 5�

�ZONES� 3� &� 6�

�ZONES� 4� &� 7�

�200� °� C�

�“RAMP”� “RAMP”�

�DESIRED� CURVE� FOR� HIGH�

�MASS� ASSEMBLIES�

�150� °� C�

�“SOAK”�

�160� °� C�

�“SPIKE”�

�170� °� C�

�205� °� TO� 219� °� C�

�PEAK� AT�

�SOLDER�

�JOINT�

�150� °� C�

�SOLDER� IS� LIQUID� FOR�

�100� °� C�

�100� °� C�

�140� °� C�

�40� TO� 80� SECONDS�

�(DEPENDING� ON�

�MASS� OF� ASSEMBLY)�

�DESIRED� CURVE� FOR� LOW�

�MASS� ASSEMBLIES�

�5� °� C�

�TIME� (3� TO� 7� MINUTES� TOTAL)�

�Figure� 16.� Typical� Solder� Heating� Profile�

�http://onsemi.com�

�10�

�T� MAX�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

MMFT960T1

MOSFET N-CH 60V 300MA SOT223

MMG3002NT1

IC AMP RF GP 3600MHZ 5.2V SOT-89

MMG3006NT1

TRANS GPA 33DBM 16-QFN

MMG3007NT1

IC AMP RF GP 6000MHZ 5V SOT-89

MMG3H21NT1

TRANS HBT 20.5DBM 19.3DB SOT-89

MMH3111NT1

TRANS GAAS HFET SOT-89

MML20211HT1

IC LNA 2GHZ 21P1DB 8DFN

MMS-1A-V2 0

SENSOR MICRO MACHINED SMD

相关代理商/技术参数

MMFT5P03HDT3

制造商:MOTOROLA 制造商全称:Motorola, Inc 功能描述:TMOS P-CHANNEL FIELD FEECT TRANSISTOR

MMFT6N03HD

制造商:MOTOROLA 制造商全称:Motorola, Inc 功能描述:TMOS POWER 6.0 AMPERES 30 VOLTS

MMFT960T1

功能描述:MOSFET 60V 300mA N-Channel RoHS:否 制造商:STMicroelectronics 晶体管极性:N-Channel 汲极/源极击穿电压:650 V 闸/源击穿电压:25 V 漏极连续电流:130 A 电阻汲极/源极 RDS(导通):0.014 Ohms 配置:Single 最大工作温度: 安装风格:Through Hole 封装 / 箱体:Max247 封装:Tube

MMFT960T1_06

制造商:ONSEMI 制造商全称:ON Semiconductor 功能描述:Power MOSFET 300 mA, 60 Volts N−Channel SOT−223

MMFT960T1G

功能描述:MOSFET 60V 300mA N-Channel RoHS:否 制造商:STMicroelectronics 晶体管极性:N-Channel 汲极/源极击穿电压:650 V 闸/源击穿电压:25 V 漏极连续电流:130 A 电阻汲极/源极 RDS(导通):0.014 Ohms 配置:Single 最大工作温度: 安装风格:Through Hole 封装 / 箱体:Max247 封装:Tube

MMFTN123

制造商:Diotec Semiconductor 功能描述:

MMFTN138

制造商:Diotec 功能描述:Bulk

MMFTN170

制造商:Diotec Semiconductor 功能描述: